Discover the crucial safety protocols and equipment needed to keep your painting crew safe, reduce accidents, and comply with regulations.

Implementing effective safety practices in your painting business is not just a regulatory requirement—it’s essential for protecting your team and ensuring the longevity of your company. Accidents can lead to costly downtime, legal issues, and harm to your reputation. By prioritizing safety, you can create a productive work environment that benefits everyone.

Understanding Common Hazards in the Painting Industry

To implement effective safety measures, you first need to understand the common hazards that painting crews face.

1. Exposure to Toxic Fumes

- Hazard: Inhalation of volatile organic compounds (VOCs) and other harmful chemicals found in paints and solvents.

- Risks: Respiratory issues, headaches, nausea, long-term health problems.

2. Falls from Heights

- Hazard: Working on ladders, scaffolding, or elevated platforms.

- Risks: Serious injuries or fatalities due to falls.

3. Injuries from Equipment

- Hazard: Misuse of tools like sprayers, sanders, and other machinery.

- Risks: Cuts, bruises, eye injuries, hearing damage.

4. Electrical Hazards

- Hazard: Contact with live electrical wires when painting near power lines or using electrical equipment.

- Risks: Electric shock, burns, electrocution.

Essential Protocols for Painting Crew Safety

Implementing structured safety protocols is crucial for minimizing risks.

1. Proper Training and Certification

- Provide Comprehensive Training: Ensure all crew members are trained in the safe use of equipment and materials.

- Certifications: Obtain necessary certifications for specialized tasks, such as working at heights or handling hazardous materials.

- Ongoing Education: Keep the team updated on the latest safety practices and regulatory changes.

2. Implementing Painting Crew Safety Guidelines

- Develop a Safety Manual: Create a detailed manual outlining all safety procedures and protocols.

- Standard Operating Procedures (SOPs): Establish SOPs for routine tasks to ensure consistency and safety.

- Emergency Action Plan: Prepare for emergencies with clear steps for evacuation, first aid, and communication.

3. Regular Safety Meetings

- Daily Briefings: Start each day with a safety briefing to discuss potential hazards.

- Feedback Sessions: Encourage crew members to share concerns or suggestions for improving safety.

- Incident Reviews: Analyze any accidents or near-misses to prevent future occurrences.

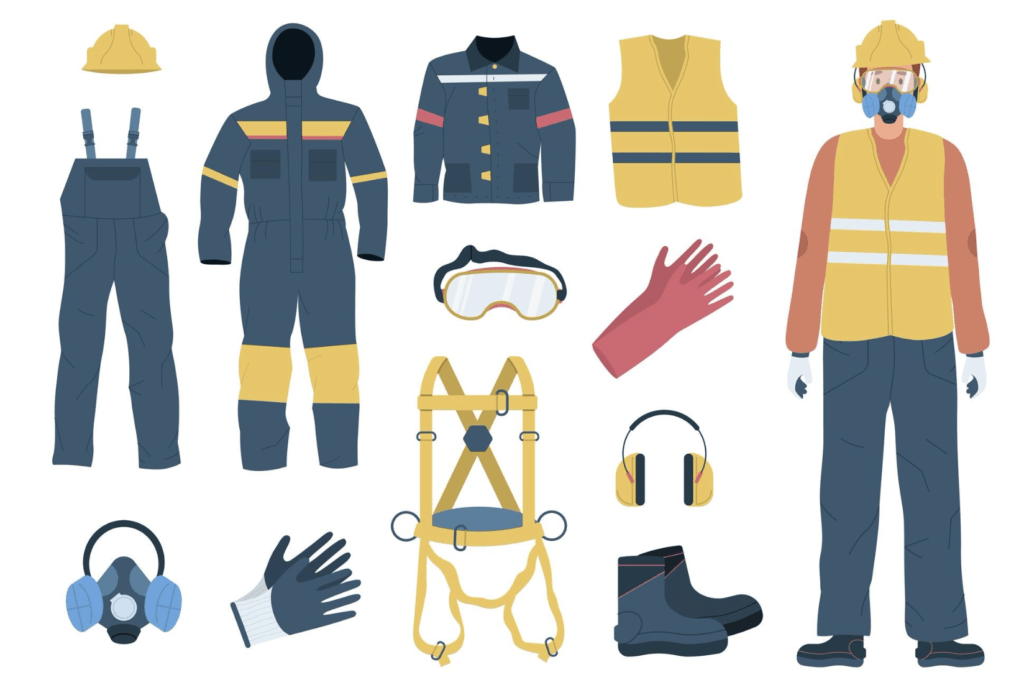

Essential Safety Equipment for Painters

Equipping your team with the right safety gear is a fundamental aspect of workplace safety.

Personal Protective Equipment (PPE)

1. Respirators

- Purpose: Protects against inhalation of harmful fumes and particles.

- Types: Half-face or full-face respirators with appropriate filters.

2. Protective Clothing

- Coveralls: Shields skin from paint, solvents, and other chemicals.

- Material: Use flame-resistant and breathable fabrics when necessary.

3. Gloves

- Chemical-Resistant Gloves: Protect hands from solvents and paints.

- Cut-Resistant Gloves: For tasks involving sharp tools or materials.

4. Safety Glasses and Goggles

- Eye Protection: Prevents paint splashes and debris from entering the eyes.

- Features: Anti-fog and impact-resistant lenses.

5. Hard Hats

- Head Protection: Essential when working on construction sites or areas with overhead hazards.

Fall Protection Gear

1. Safety Harnesses

- Use When: Working at heights above six feet.

- Features: Should be properly fitted and inspected regularly.

2. Guardrails and Safety Nets

- Purpose: Provide collective protection on elevated work platforms.

Proper Use of Ladders and Scaffolding

- Inspection: Regularly check for defects or damage.

- Setup: Ensure stable and level placement.

- Usage Guidelines: Follow the manufacturer’s instructions and OSHA regulations.

Compliance with Safety Regulations

Adhering to regulatory standards is non-negotiable for legal and ethical reasons.

Occupational Safety and Health Administration (OSHA) Standards

- Stay Informed: Regularly review OSHA’s Painting Industry Standards for updates.

- Recordkeeping: Maintain logs of training, inspections, and incidents as required.

Proper Documentation

- Safety Data Sheets (SDS): Keep accessible records of all chemicals and materials used.

- Permits and Certifications: Ensure all legal documents are up-to-date.

Painting Crew Safety Inspections

- Regular Audits: Conduct internal and external safety inspections.

- Compliance Checks: Address any violations immediately to avoid penalties.

Creating a Safety Culture

Fostering a culture that prioritizes safety encourages everyone to take responsibility.

Encourage Hazard Reporting

- Open Communication: Create an environment where crew members feel comfortable reporting hazards.

- Anonymous Options: Provide ways to report issues without fear of retaliation.

Reward Safe Behavior

- Incentive Programs: Recognize and reward teams or individuals who demonstrate exemplary safety practices.

- Positive Reinforcement: Use positive feedback to promote ongoing adherence to safety protocols.

Continuous Training

- Refreshers and Workshops: Regularly update training to keep safety top-of-mind.

- Cross-Training: Teach team members multiple roles to understand the importance of safety in all aspects.

The Benefits of Prioritizing Safety

- Reduced Accidents: Fewer workplace injuries lead to less downtime and higher productivity.

- Lower Costs: Minimizing accidents reduces medical expenses and insurance premiums.

- Enhanced Reputation: A strong safety record builds trust with clients and can be a competitive advantage.

- Employee Satisfaction: Workers are more engaged and loyal when they feel their well-being is valued.

Investing in essential safety practices for your painting crew is a strategic decision that protects your team and strengthens your business. By understanding common hazards, implementing robust safety protocols, equipping your team with the right gear, and fostering a safety-first culture, you not only comply with regulations but also pave the way for sustainable success.

Ready to enhance the safety practices in your painting business? Discover how our consulting services can help you implement effective safety protocols and training programs. Contact us today for a free consultation.

Frequently Asked Questions

Q: What is the most important piece of safety equipment for painters?

A: While all safety equipment is important, respirators are crucial as they protect against inhalation of harmful fumes and particles.

Q: How often should safety training be conducted?

A: Initial training should be provided upon hiring, with regular refresher courses and updates whenever new equipment or procedures are introduced.

Q: Are safety meetings necessary if there haven’t been any recent accidents?

A: Yes, regular safety meetings are essential for maintaining awareness and preventing complacency, which can lead to accidents.